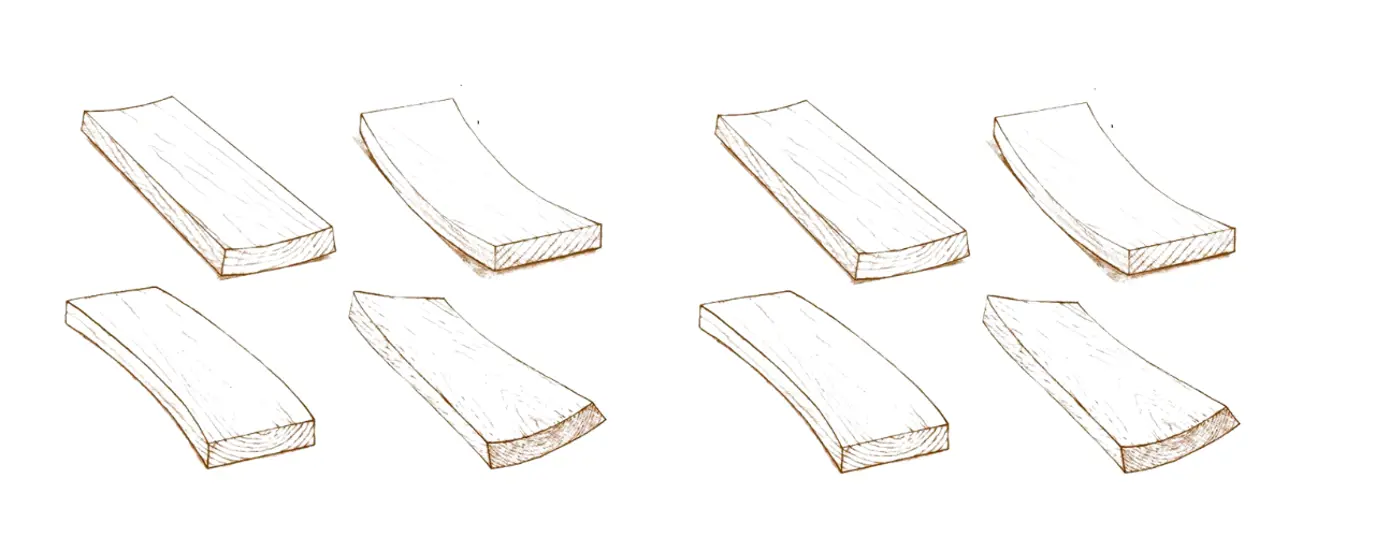

Wood warping is a common problem that can occur in various projects and structures. It happens when the timber fibers shrink or swell because of changes in moisture content, causing the wood to bend, twist, or cup. In this article, we'll explore the causes of warping, prevention methods, and solutions to address existing warping issues.

Wood warping results from its natural properties. As a hygroscopic material, wood absorbs or releases moisture depending on the surrounding environment's humidity levels. This fluctuation in moisture content causes the fibres to expand or contract, leading to warping.

Some timber species are more prone to warping than others. Hardwoods like Oak and Silvertop Ash are generally more stable, while softwoods like Pine and Cedar are more susceptible to warping due to their higher moisture content and softer fibres.

If warping has already occurred, there are several approaches you can take:

Prevention is always better than addressing warping after it occurs. Here are some effective strategies:

Proper maintenance is crucial for preventing and addressing wood warping over time. Intergrain recommends regular cleaning and reapplication of our protective wood coatings. By being proactive, you can protect your timber surfaces from environmental factors that can cause warping. This will help extend the lifespan and enhance the beauty of your wood.

Using our woodcare products and following prevention strategies can reduce the risk of warping. This will keep your projects in good condition for many years.